Home > FAQ

| 1. Why should you use Enclosure Cooling Unit | |

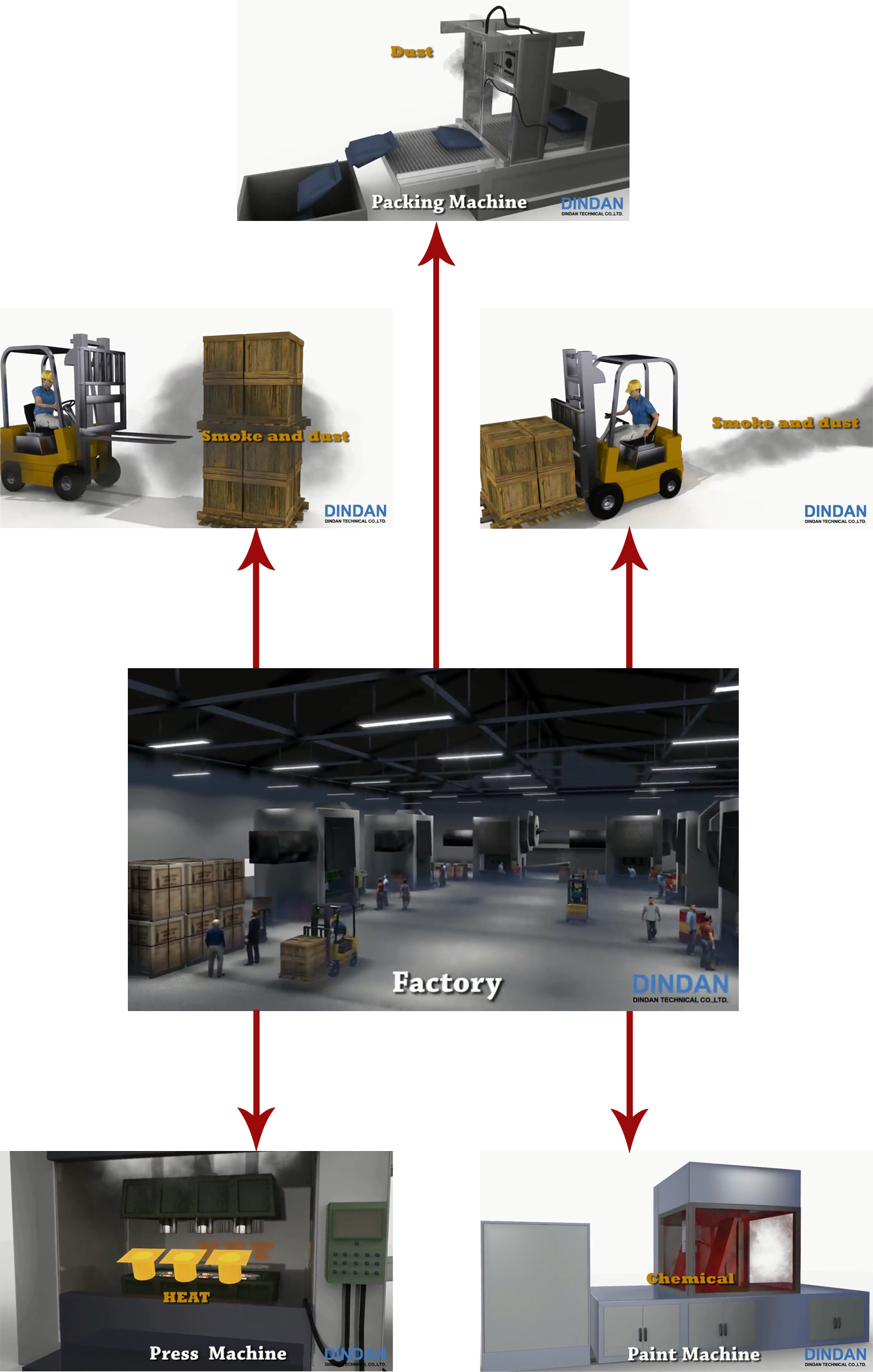

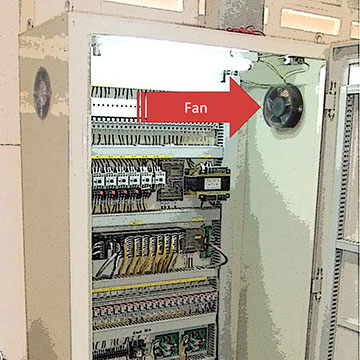

Fig. 1 Showing pollution in normal factories

|

In a factory, without a good ventilation serious hazard could occur. Whether it may be a packing machine, forklift, crates, paint machine, or pressing machine seen in Fig.1. Dust, smoke, heat, or chemical could cause damage to machine and worker's health. |

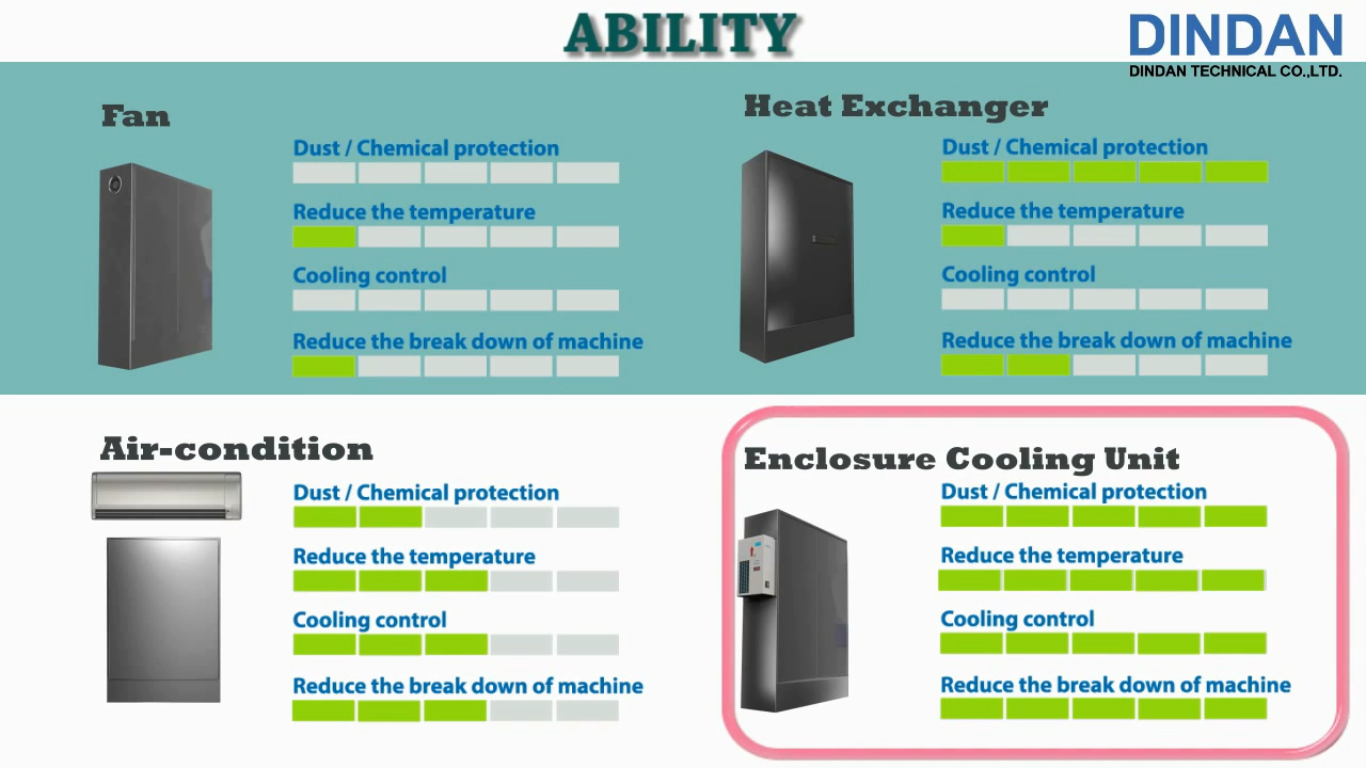

Fig.2 Show ability and durability of different types of cooler compare to no cooling equipment

|

|

There are 4 different ways to cool down your machines; fan type, heat exchanger type, air-condition type, and enclosure cooling unit type.

There are 4 main factors we consider when measure the ability and efficiency of cooling equipment.

The solution for dispersing heat from electrical control units should be considered from multiple factors such as environmental and ambient temperature of control cabinet, size of the control cabinet, power of electric device in control cabinet, surrounding area, energy consumption of each the thermal variations and more. |

|

|

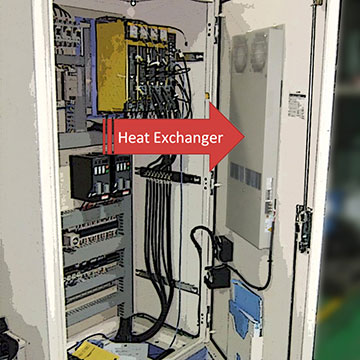

Heat exchanger

|

|

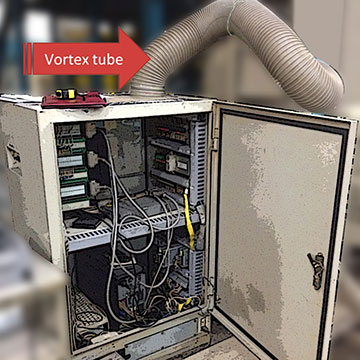

Vortex tube

|

|

Air-condition

|

|

Fan

|

|

Cooling Unit

This is an outstanding solution to solving the issue of heat retention within a control unit and it can also prevent humidity and contaminants (which can cause damage to components and equipment within the unit) better than other methods.

It works as a closed system that generates coolness within a component that supplies cold air inside the control unit to disperse heat. The heat is drawn into an air duct to be distributed to the outside.

One just needs to install the component to an opening cut into the control cabinet and seal the control cabinet to create a boundary for maintaining coolness within. |

| The conclusion is that it is very important to consider many factors in selection the best value between the different methods of heat dispersion before making an investment. | |

| 2. Why should you use Dindan's services | |

Attention in designing the cooling unit to achieve its high performance,

we have continuously researched

and developed every engineering aspects numerically. |

|

|

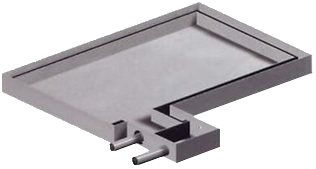

Careful with condensation

Drainage of condensation is the most hazardous to those machines installed cooling unit |

|

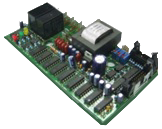

Hi-prosent control

The controller is functionful with the protective of every failure of system |

|

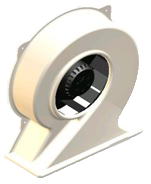

Aerodynamic for ventilation

Air flow and its pressure are fully considered with its flow impedance in order to maximise its ventilation performance then cooling performance obtained. |

|

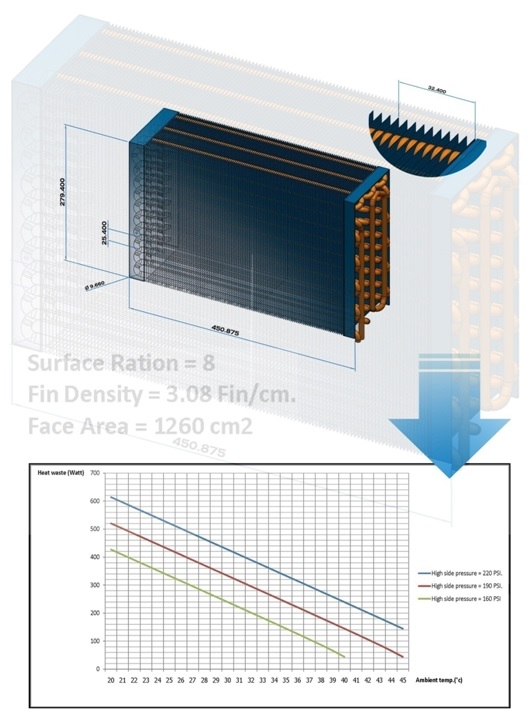

Computational design for heat exchanger

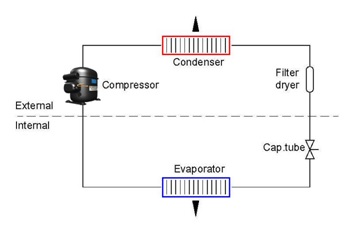

After simply dimension for the heat exchanger is outlined. Heat transfering in condenser and evaporater are initiated by computation method for consider the stability of the heat exchanging in various ambient conditions with refrigerant property.

|

Fig.1 : Schematic diagram for cooling unit |

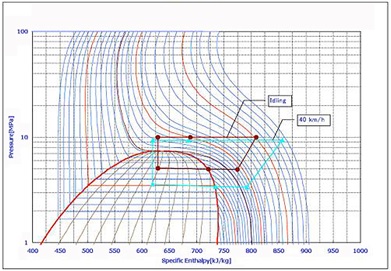

Thermodynamic Examination

In order to obtain proper designed condition of cooling system we monitor every thermodynamic quantity with our special software. Over high pressure abovecompressure shorten it operating life. Balancing between high pressure and low pressure is the factor for cooling performance. |

Fig.2 : Pressure and Enthalpy diagram for refrigerant in refrigeration cycle |

Fig.3 : Realtime thermodynamic response interfacing software |