DINDAN company designed the product following the International Standards to provide the high quality product and safety for the user.

DINDAN products had been tested and inspectedby the International Institute compliance with the International Standards.

ROHS (Restriction of Harzardous Substances)

The definition and aim of the RoHS directive is quite simple. The RoHS directove aims to restrict certain dangerous sunstances commonly used in electronic equipment. Is intended to provide the product that safe for user and environment.

Electromagnetic (EMC)

All electrical and electronic devices, or installation, influence each other when either interconnected or placed in close proximity. This can affect interference of Electromagnetic. As a result to device has a irregular operation.

CE

Stands for Communauté Européenne. CE marking signifies that a product complies with relevant safety, health or environmental regulations across the European Economic Area (EAA).

|

Technical information

Protective equipment

Refrigeration system has been tested with high pressure device at 350 PSI. This series of cooling unit also contains electronic circuit and sensors are installed at significant points to monitor any defect of refrigeration cycle in order to reduce burden of the user and to prolong use of life of cooling unit at more costeffective practice.

Note

- LED light will display green color (continuously) to indicate condition.

- Under any abnormal condition, please see the manual.

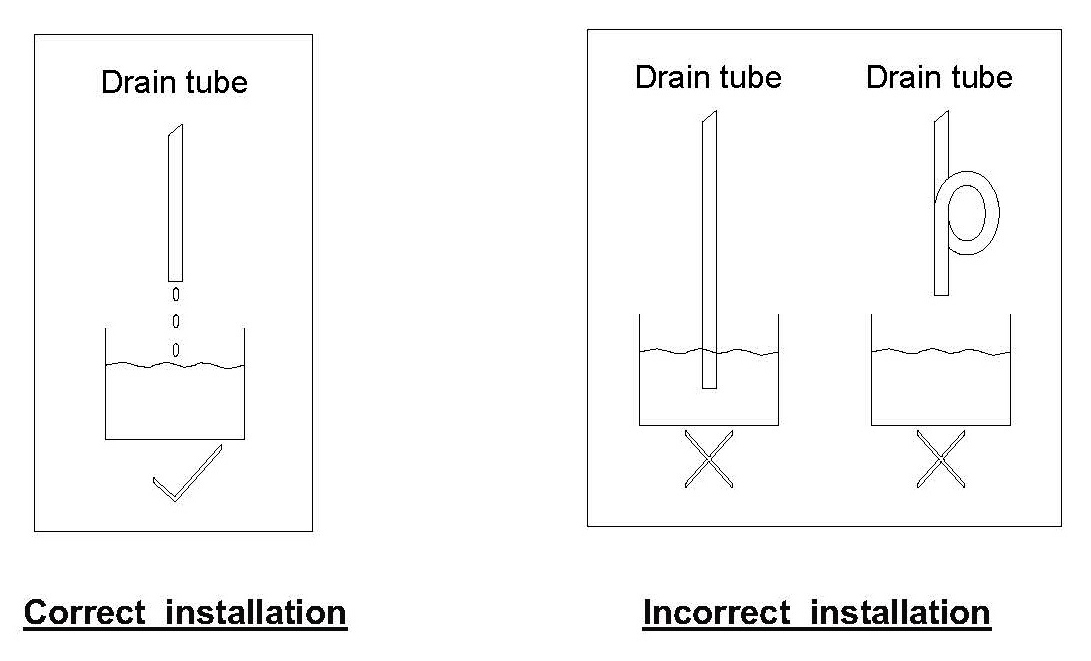

Drainage

Drainage of condensed water from cooling system shall be done by inserting drain tube under drainpan and trying not to left it twisted.Make sure the other end of draing tube is not lower than water level in the container, in order to avoid water reflux.

|

|

Notification

- Before, drilling, and cut. Should use clean dry cloth, or the inventory doesn't lead the electricity, covers the euipment for protects iron dust touches the electrical equiptment while installing. (Incase of machine still operate.)

- Cooling unit should be installed in the good conition area.

- Check vertical and horizontal level of which their error shall be allowable within +/- 2° in order to facillitate efficient drainage.

-Should always install gasket between Installation plate and Cooling Unit before hang the cooling unit on the installation plate.

- In order to minimise water condensation, cabinet doors should be tightly closed during operation.

|

- Circulation fan should be installed in cabinet if various equipment is densely installed inside.

- In order to obtain highest performance and durability, repair and alteration of cooling iunit should be under care of distributor.

- Should not adjust temperature difference more than 10° C between environmental temperature and cooling space, to prevent moisture build up on some part in the cooling area when you open the cabinet panel.

- If it is necessary to set temperature lower than 25° C, it is recommended to use precision cooling unit or contact your Professional Maker.

-The equipments that are locate in the cooling air stream have to be obstructed by the insulater to prevent water condensation. |